Cov lus qhia dav dav no piv rau 25 cov ntaub ntawv siv feem ntau siv hauv CNC machining thiab pab koj xaiv qhov zoo rau koj daim ntawv thov.

CNC machining tuaj yeem tsim cov khoom los ntawm yuav luag txhua yam hlau lossis yas.Qhov no yog qhov teeb meem, muaj ntau yam khoom siv rau cov khoom tsim los ntawm CNC milling thiab tig.Kev xaiv qhov tsim nyog rau koj daim ntawv thov tuaj yeem yog qhov nyuaj heev, thiab nkag siab txog qhov zoo thiab kev siv zoo tshaj plaws ntawm txhua yam khoom muaj peev xwm yog qhov tseem ceeb.

Hauv tsab xov xwm no, peb sib piv cov khoom siv CNC feem ntau, hais txog cov khoom siv hluav taws xob thiab thermal, cov nqi thiab cov ntawv siv (thiab pom zoo).

Koj xaiv cov ntaub ntawv CNC zoo li cas?

Thaum koj tab tom tsim ib feem los ua CNC machined, xaiv cov ntaub ntawv zoo yog qhov tseem ceeb.Nov yog cov kauj ruam yooj yim uas peb pom zoo ua raws li cov khoom siv zoo rau koj qhov kev cai.

Txhais cov khoom yuav tsum tau: Cov no tuaj yeem suav nrog txhua yam, thermal lossis lwm yam khoom xav tau, nrog rau cov nqi thiab qhov chaw tiav.Xav txog seb koj yuav siv koj cov khoom li cas thiab qhov chaw zoo li cas lawv yuav nyob hauv.

Txheeb xyuas cov ntaub ntawv sib tw: Pin down ob peb cov ntaub ntawv sib tw uas ua tiav tag nrho (lossis feem ntau) ntawm koj qhov kev tsim qauv.

Xaiv cov khoom tsim nyog tshaj plaws: Kev sib haum xeeb feem ntau yuav tsum muaj nyob ntawm no ntawm ob lossis ntau dua ntawm cov qauv tsim (piv txwv li, kev ua haujlwm zoo thiab cov nqi).

Hauv kab lus no, peb yuav tsom mus rau theem ob.Siv cov ntaub ntawv qhia hauv qab no, koj tuaj yeem txheeb xyuas cov ntaub ntawv uas haum rau koj daim ntawv thov, thaum khaws koj qhov project ntawm pob nyiaj siv.

Dab tsi yog Hubs cov lus qhia rau kev xaiv cov khoom siv rau CNC?

Hauv cov lus hauv qab no, peb nthuav tawm cov yam ntxwv cuam tshuam ntawm cov khoom siv CNC feem ntau, sib sau los ntawm kev tshuaj xyuas cov ntaub ntawv muab los ntawm cov khoom lag luam.Peb faib cov hlau thiab yas ua ob hom sib txawv.

Cov hlau feem ntau yog siv rau hauv cov ntawv thov uas xav tau lub zog siab, hardness thiab thermal kuj.Plastics yog cov khoom siv hnyav nrog ntau yam ntawm lub cev, feem ntau siv rau lawv cov tshuaj tiv thaiv thiab hluav taws xob rwb thaiv tsev.

Hauv peb qhov kev sib piv ntawm cov ntaub ntawv CNC, peb tsom rau cov khoom siv dag zog (tshwj xeeb yog lub zog tensile yield), machinability (qhov yooj yim ntawm machining cuam tshuam rau CNC pricing), nqi, hardness (tsuas yog rau cov hlau) thiab kub tsis kam (tsuas yog rau cov yas).

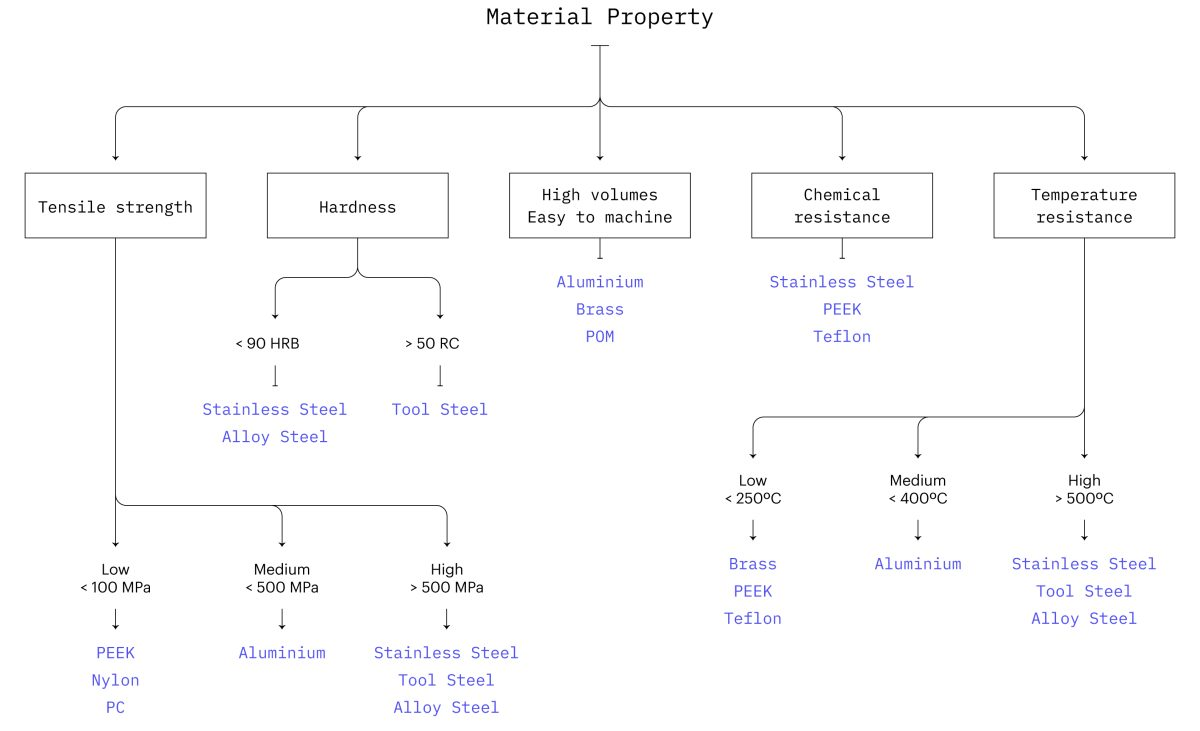

Ntawm no yog ib qho infographic uas koj tuaj yeem siv los ua cov ntaub ntawv ceev ceev los txheeb xyuas cov ntaub ntawv CNC uas haum rau cov kev xav tau tshwj xeeb engineering:

Aluminium yog dab tsi?Lub robust, economical alloy

Ib feem ua los ntawm Aluminium 6061

Aluminium alloys muaj lub zog-rau-qhov hnyav piv, siab thermal thiab hluav taws xob conductivity thiab ntuj tiv thaiv corrosion.Lawv yog cov yooj yim rau tshuab thiab nqi-npaum nyob rau hauv tej, feem ntau ua rau lawv cov kev xaiv pheej yig tshaj plaws rau kev tsim prototypes thiab lwm yam ntawm qhov chaw.

Thaum txhuas alloys feem ntau muaj qis zog thiab hardness dua steels, tab sis lawv tuaj yeem ua anodized, tsim ib qho nyuaj, tiv thaiv txheej ntawm lawv qhov chaw.

Cia peb rhuav tshem ntau yam ntawm aluminium alloys.

❖ Aluminium 6061 yog qhov feem ntau siv, dav siv aluminium alloy, nrog lub zog zoo-rau-hnyav piv thiab zoo heev machinability.

❖ Aluminium 6082 muaj cov khoom zoo sib xws thiab cov khoom siv rau 6061. Nws tau siv ntau dua hauv Tebchaws Europe (raws li nws ua raws li Cov Qauv Askiv).

❖ Aluminium 7075 yog cov alloy feem ntau siv hauv kev siv aerospace qhov twg qhov hnyav txo yog qhov tseem ceeb.Nws muaj cov khoom ua kom qaug zog zoo heev thiab tuaj yeem kho cua sov kom siab zog thiab hardness, ua rau nws piv rau steels.

❖ Aluminium 5083 muaj lub zog ntau dua li lwm cov txhuas alloys thiab tshwj xeeb tiv thaiv dej hiav txwv.Qhov no ua rau nws zoo rau kev tsim kho thiab kev siv marine.Nws kuj yog ib qho kev xaiv zoo heev rau vuam.

Khoom nta:

❖ Qhov ntom ntom ntawm aluminium alloys: 2.65-2.80 g / cm3

❖ tuaj yeem ua anodized

❖ Tsis-magnetic

Stainless hlau yog dab tsi?Lub zog, ruaj khov alloy

Ib feem ua los ntawm Stainless Hlau 304

Stainless hlau alloys muaj lub zog siab, siab ductility, zoo heev hnav thiab corrosion kuj thiab tuaj yeem yooj yim welded, machined thiab polished.Nyob ntawm lawv cov muaj pes tsawg leeg, lawv tuaj yeem yog (tseem ceeb) tsis sib nqus lossis sib nqus.

Cia peb rhuav tshem cov hom stainless hlau peb muab rau ntawm lub platform.

❖ Stainless hlau 304 yog cov hlau tsis muaj hlau ntau tshaj plaws.Nws muaj zoo mechanical zog thiab zoo machinability.Nws yog resistant rau feem ntau ib puag ncig tej yam kev mob thiab corrosive xov xwm.

❖ Stainless hlau 316 yog lwm hom stainless hlau alloy nrog cov khoom siv zoo sib xws rau 304. Nws muaj kev tiv thaiv corrosion thiab tshuaj lom neeg ntau dua, txawm li cas los xij, tshwj xeeb tshaj yog rau cov dej ntsev (xws li dej hiav txwv), yog li nws feem ntau zoo dua rau kev cuam tshuam nrog ib puag ncig hnyav.

❖ Stainless hlau 2205 Duplex muaj lub zog siab tshaj plaws (ob zaug ntawm cov hlau tsis sib xws) thiab zoo heev tiv thaiv corrosion.Nws tau siv nyob rau hauv qhov chaw huab cua, nrog ntau daim ntawv thov hauv Roj & Roj.

❖ Stainless hlau 303 muaj qhov toughness zoo heev, tab sis qis corrosion kuj piv rau 304. Vim nws zoo heev machinability, nws yog feem ntau siv nyob rau hauv high-volume daim ntaub ntawv, xws li ua txiv ntseej thiab bolts rau aerospace.

❖ Stainless hlau 17-4 (SAE qib 630) muaj cov cuab yeej cuab tam piv rau 304. Nws tuaj yeem ua nag lossis daus los rau qib siab heev (piv rau cov cuab yeej steel) thiab muaj cov tshuaj tiv thaiv zoo heev, ua rau nws tsim nyog rau kev ua haujlwm siab heev, xws li kev tsim cov hniav rau cua turbines.

Khoom nta:

❖ Qhov ceev: 7.7-8.0 g / cm3

❖ Non-magnetic stainless hlau alloys: 304, 316, 303

❖ Sib nqus stainless hlau alloys: 2205 Duplex, 17-4

Cov hlau me me yog dab tsi?Lub hom phiaj dav dav

Ib feem ua los ntawm Mild Steel 1018

Cov hlau me metseem hu ua low-carbon steels thiab muaj cov khoom siv zoo, machinability thiab zoo weldability.Vim tias lawv yog tus nqi qis, cov neeg tsim khoom siv lawv rau ntau lub hom phiaj kev siv, xws li jigs thiab fixtures.Cov hlau me me muaj qhov cuam tshuam rau corrosion thiab tshuaj lom neeg puas tsuaj.

Cia peb rhuav tshem cov hlau me me uas muaj nyob rau ntawm lub platform.

❖ Mild steel 1018 yog ib qho kev siv dav dav nrog kev ua haujlwm zoo thiab weldability thiab zoo heev toughness, lub zog thiab hardness.Nws yog qhov feem ntau siv me me hlau alloy.

❖ Mild steel 1045 yog ib qho nruab nrab carbon steel nrog zoo weldability, zoo machinability thiab siab zog thiab cuam tshuam tsis kam.

❖ Mild steel A36 yog cov qauv hlau uas muaj kev sib txuas zoo.Nws yog haum rau ntau yam kev lag luam thiab kev tsim kho daim ntawv thov.

Khoom nta:

❖ Qhov ceev: 7.8-7.9 g / cm3

❖ Sib Nqus

Alloy steel yog dab tsi?Lub tougher, hnav-resistant alloy

Ib feem ua los ntawm cov hlau alloy

Alloy steels muaj lwm cov ntsiab lus alloying ntxiv rau cov pa roj carbon, uas ua rau muaj kev txhim kho hardness, toughness, qaug zog thiab hnav tsis kam.Zoo ib yam li cov hlau me me, cov hlau tsis muaj zog yog qhov cuam tshuam rau corrosion thiab tawm tsam los ntawm cov tshuaj

❖ Alloy steel 4140 muaj cov khoom siv zoo tag nrho, nrog lub zog zoo thiab tawv.Cov hlau no haum rau ntau daim ntawv thov kev lag luam tab sis tsis pom zoo rau vuam.

❖ Alloy steel 4340 tuaj yeem kho cua sov kom siab zog thiab tawv, thaum tuav nws zoo toughness, hnav tsis kam thiab qaug zog.Qhov no alloy yog weldable.

Khoom nta:

❖ Qhov ceev: 7.8-7.9 g / cm3

❖ Sib Nqus

Cov cuab yeej steel yog dab tsi?Qhov tshwj xeeb tawv thiab resistant alloy

Ib feem machined los ntawm cov cuab yeej steel

Cov cuab yeej steelyog cov hlau alloys nrog tshwj xeeb siab hardness, nruj, abrasion thiab thermal kuj, tsuav yog lawv undergoKev kho cua sov.Lawv yog siv los tsim cov cuab yeej tsim khoom (li no lub npe) xws li tuag, nyiaj muas thiab pwm.

Cia peb rhuav tshem cov cuab yeej hlau peb muab ntawm Hubs.

❖ Tool steel D2 yog ib qho hnav-resistant alloy uas khaws nws cov hardness mus rau qhov kub ntawm 425 ° C.Nws yog feem ntau siv los tsim cov cuab yeej txiav thiab tuag.

❖ Cov cuab yeej steel A2 yog cov khoom siv dav dav dav dav dav dav hlau uas muaj cov tawv tawv zoo thiab zoo heev qhov ntev ntawm qhov kub siab.Nws yog feem ntau siv los tsim cov tshuaj molding tuag.

❖ Tool steel O1 yog cov roj-hardened alloy nrog lub siab hardness ntawm 65 HRC.Nws yog feem ntau siv rau riam thiab txiav cov cuab yeej.

Khoom nta:

❖ Qhov ceev: 7.8 g / cm3

❖ Hom hardness: 45-65 HRC

Dab tsi yog tooj dag?Lub conductive & cosmetic alloy

Brass C36000 ib feem

tooj dagyog ib tug hlau alloy nrog zoo machinability thiab zoo heev hluav taws xob conductivity, ua rau nws zoo tagnrho rau daim ntaub ntawv uas yuav tsum tau tsis muaj kev sib txhuam.Feem ntau koj yuav pom cov khoom siv tooj dag siv rau kev tsim vaj tsev (kub nthuav dav).

Nov yog tooj dag peb muab ntawm Hubs.

❖ Brass C36000 yog cov khoom siv muaj zog tensile thiab ntuj corrosion kuj.Nws yog ib qho ntawm cov khoom siv tau yooj yim tshaj plaws, yog li nws feem ntau siv rau cov ntawv thov ntim siab.

Khoom nta:

❖ Qhov ceev: 8.4-8.7 g / cm3

❖ Tsis-magnetic

ABS yog dab tsi?Thermoplastic prototyping

Ib feem ua los ntawm ABS

ABSyog ib qho ntawm cov khoom siv thermoplastic feem ntau muab cov khoom siv zoo, zoo heev cuam tshuam lub zog, siab kub tsis kam thiab zoo machinability.

ABS muaj qhov ntom ntom, ua rau nws zoo tagnrho rau kev siv lub teeb.CNC machined ABS qhov feem ntau yog siv los ua qauv ua ntej kev tsim khoom loj nrog kev txhaj tshuaj molding.

Khoom nta:

❖ Qhov ceev: 1.00-1.05 g / cm3

Nylon yog dab tsi?Engineering thermoplastic

Ib feem ua los ntawm nylon

Nylon(aka polyamide (PA)) yog ib qho thermoplastic uas feem ntau siv rau kev siv engineering, vim nws cov khoom siv zoo heev, muaj kev cuam tshuam zoo zog thiab muaj tshuaj lom neeg thiab puas.Nws yog susceptible rau dej thiab noo noo nqus.

Nylon 6 thiab nylon 66 yog cov qib uas feem ntau siv hauv CNC machining.

Khoom nta:

❖ Qhov ceev: 1.14 g / cm3

Polycarbonate yog dab tsi?Thermoplastic nrog kev cuam tshuam lub zog

Ib feem tsim los ntawm polycarbonate

Polycarbonate yog ib qho thermoplastic uas muaj zog toughness, zoo machinability thiab zoo heev cuam tshuam lub zog (zoo dua li ABS).Nws feem ntau yog pob tshab, tab sis tuaj yeem dyed rau ntau yam xim.Cov yam ntxwv no ua rau nws zoo tagnrho rau ntau yam kev siv, suav nrog cov khoom siv fluidic lossis automotive glazing.

Khoom nta:

❖ Qhov ceev: 1.20-1.22 g / cm3

POM (Delrin) yog dab tsi?Qhov feem ntau machinable CNC yas

Ib feem ua los ntawm POM (Delrin)

POM feem ntau paub los ntawm kev lag luam lub npe Delrin, thiab nws yog ib qho kev lag luam thermoplastic nrog lub siab tshaj plaws machinability ntawm cov yas.

POM (Delrin) feem ntau yog qhov kev xaiv zoo tshaj plaws thaum CNC machining yas qhov chaw uas yuav tsum tau siab precision, siab tawv, tsis muaj kev sib txhuam, zoo heev dimension stability ntawm siab kub thiab tsawg heev nqus dej.

Khoom nta:

❖ Qhov ceev: 1.40-1.42 g / cm3

PTFE (Teflon) yog dab tsi?Qhov kub siab tshaj thermoplastic

Ib feem ua los ntawm PTFE

PTFE, feem ntau hu ua Teflon, yog ib qho kev lag luam thermoplastic nrog cov tshuaj zoo heev thiab thermal tsis kam thiab qis tshaj coefficient ntawm kev sib txhuam ntawm cov khoom paub.Nws yog ib qho ntawm ob peb cov yas uas tuaj yeem tiv taus kev ua haujlwm kub siab tshaj 200 degrees Celsius thiab yog ib qho hluav taws xob zoo heev.Nws kuj muaj cov khoom siv tshuab ntshiab thiab feem ntau yog siv los ua ib lub hauv ob sab phlu lossis ntxig rau hauv ib qho kev sib dhos.

Khoom nta:

❖ Qhov ceev: 2.2 g / cm3

HDPE yog dab tsi?Sab nraum zoov & kav dej thermoplastic

Ib feem ua los ntawm HDPE

High-density polyethylene (HDPE)yog ib qho thermoplastic nrog lub zog-rau-hnyav piv, muaj kev cuam tshuam lub zog thiab zoo huab cua tsis kam.HDPE yog lub teeb yuag thiab haum rau siv sab nraum zoov thiab kav dej.Zoo li ABS, nws feem ntau siv los tsim cov qauv ua ntej Txhaj Moulding.

Khoom nta:

❖ Qhov ceev: 0.93-0.97 g / cm3

PEEK yog dab tsi?Cov yas los hloov hlau

Ib feem tsim los ntawm PEEK

PEByog ib qho kev ua tau zoo engineering thermoplastic nrog cov khoom siv kho tshuab zoo heev, thermal stability tshaj qhov kub thiab txias thiab ua haujlwm zoo rau feem ntau cov tshuaj.

PEEK feem ntau yog siv los hloov cov khoom hlau vim nws qhov siab zog-rau-qhov hnyav piv.Cov qib kho mob kuj muaj, ua rau PEEK haum rau kev siv biomedical.

Khoom nta:

❖ Qhov ceev: 1.32 g / cm3

Cov lus nug uas nquag nug

❖ Dab tsi yog qhov zoo ntawm CNC machining nrog hlau?

Cov hlau yog qhov zoo tagnrho rau kev tsim cov ntawv thov uas xav tau lub zog siab, hardness thiab / lossis txhim khu kev qha tiv thaiv rau qhov kub thiab txias.

Qhov chaw ntawm tsab xov xwm:https://www.hubs.com/knowledge-hub/?topic=CNC+machining

Post lub sij hawm: May-10-2023